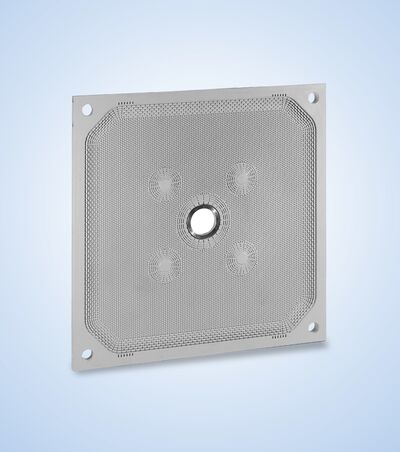

Filter plates

Polypropylene filter plates are key components of filter presses that determine the efficiency of the entire separation and dewatering process. Thanks to the use of high-quality monolithic or foamed polypropylene, the plates offer an excellent weight-to-strength ratio and complete chemical resistance in harsh industrial conditions.

Modern production technologies enable adaptation of plates to the most demanding processes – from standard chamber applications to advanced membrane systems with operating pressure up to 30 bar.

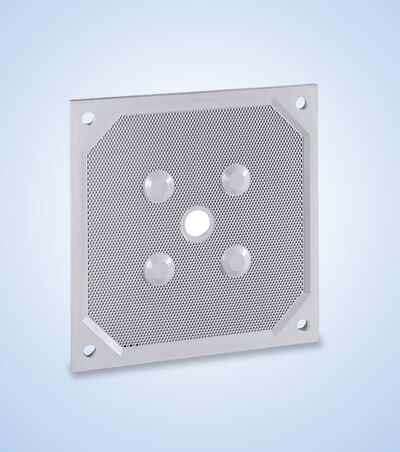

Types of chamber filter plates

- Economical, reliable filtration equipment

- Thickness 25–50 mm, pressure up to 16 bar

- Various inlet positions: central, corner, external

- Increased strength at higher pressure

- Thickness 25–50 mm, pressures up to 16 bar

- Possibility of operation in more demanding process conditions

- Equipped with EPDM, NBR, FKM (Viton) or FDA compliant seals

- Durable, tight solution for demanding processes, including ATEX

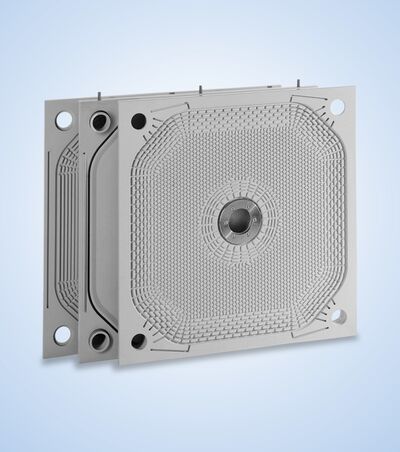

Types of membrane filter plates

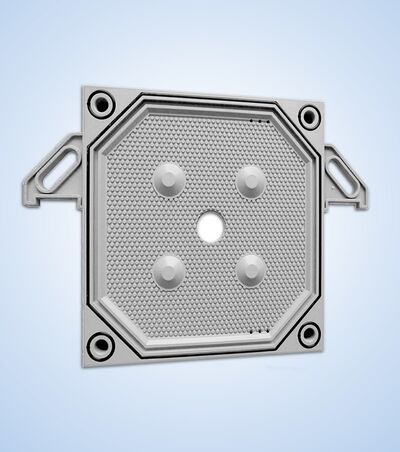

KM bloc – standard membrane plates

- Concave membrane enables uniform dewatering and better washing

- Pressing pressure up to 16 bar, width up to 2,500 mm

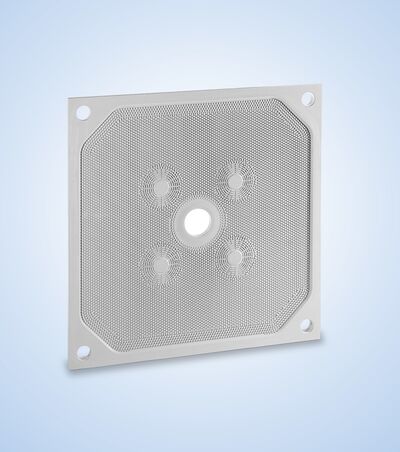

KM UM bloc – “open chamber” membrane

- Equipped with embossed edges, resistant even when the chamber is unfilled or poorly filled

- Optimal efficiency and process reliability

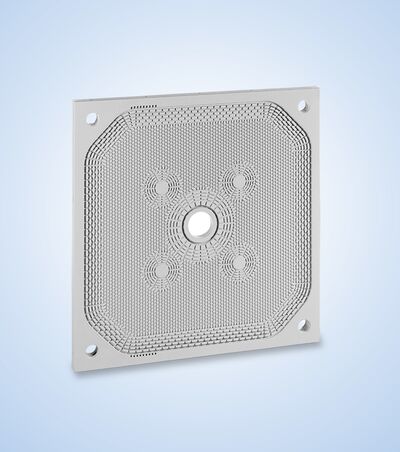

KM UM HD bloc – high-pressure membrane

- Membranes resistant to pressing up to 30 bar

- Increased efficiency of sludge dewatering

KM RUM / KM RUD – replaceable membrane halves

- Membrane mounted with clips or straps – quick and economical maintenance

- Up to 30 bar pressing, “mixed pack” configurations possible

Mixed Pack

- Combination of chamber and membrane plates – optimization of costs and process operation

Comprehensive technical support

We provide:

- Process analysis and selection of appropriate plates

- Adaptation to existing presses or delivery with complete accessories (frames, seals, clamps)

- Post-implementation service, training and logistics

- Possibility of regeneration and modernization of plates already used by the customer

Our benefits

- Flexibility of choice – chamber plates, membrane plates, replaceable membranes

- Efficiency – shorter cycles, better dewatering, lower energy and water consumption

- Durability – chemical resistance and high pressure resistance

- Customization – solutions tailored to customer needs

Distribution – Consulting – Representation

(official partner Lenser Filtration GmbH)

As the official and only representative of Lenser Filtration GmbH in Poland – the German leader in filtration technologies – we offer a complete range of chamber and membrane filter plates adapted to the most demanding industrial processes. Our plates are made of monolithic or foamed polypropylene, which guarantees an excellent mass-to-strength ratio, chemical resistance and reliability in difficult working conditions.

Get a personalized offer

Our team of experts will answer all your questions and advise you on the best solution for your business.